Measure for Aluminum Exterior Hurricane Bahama Shutters

Ordering aluminum hurricane Bahama shutters is easy, but measurements must be taken carefully. Expect to spend about 5-10 minutes per window to obtain proper measurements.

Understanding Aluminum Bahama Shutters

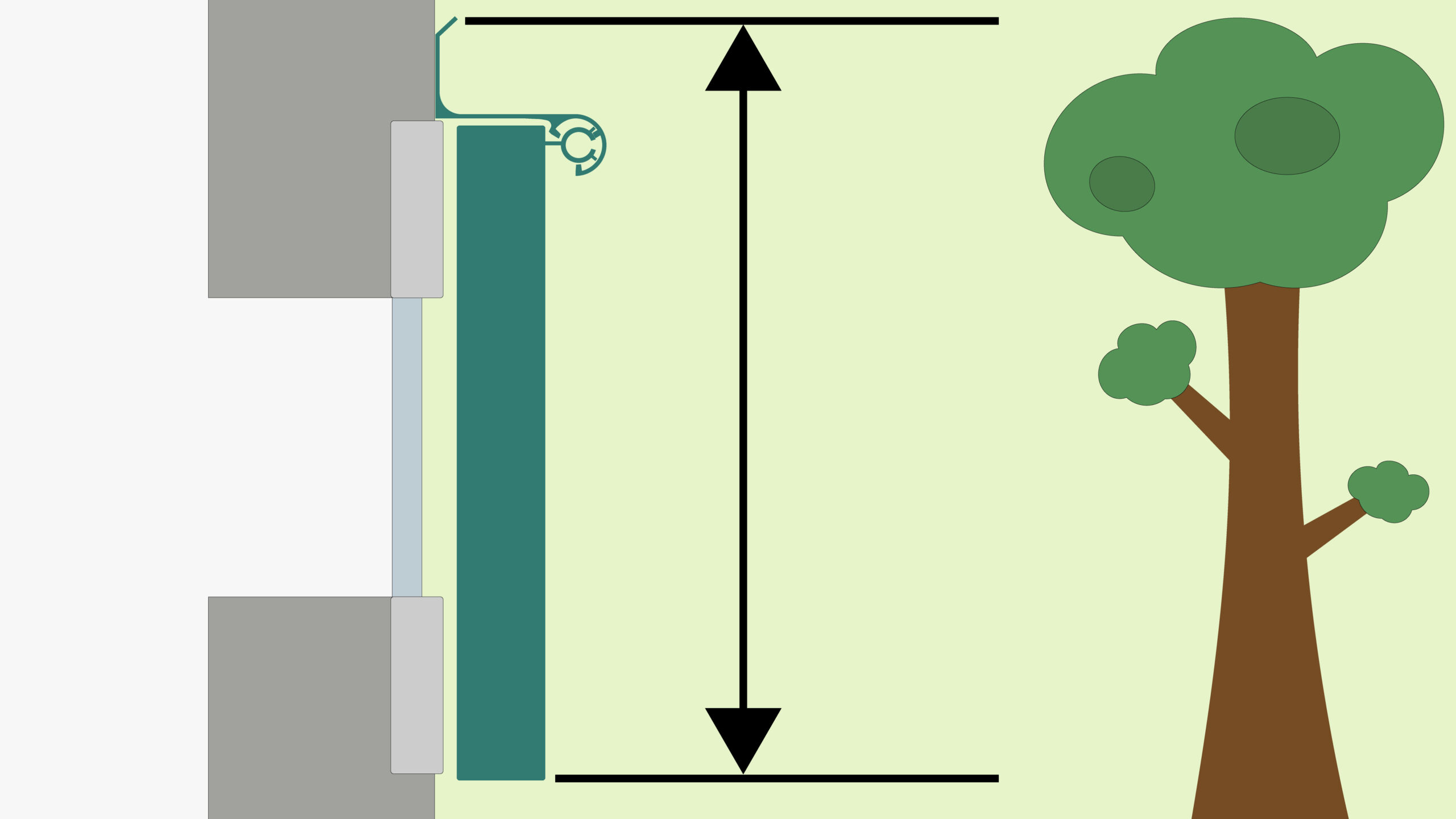

Unlike colonial-style shutters that flank the window, Bahama aluminum shutters hinge at the top of the window and lift open from the bottom. Bahama shutters are extremely popular in coastal regions for their tropical appearance and to protect vulnerable windows from hurricanes and tropical storms. In moderate weather, they provide shade and privacy so windows can remain open to invite fresh ocean breezes.

Measuring for Bahama Aluminum Shutters

To ensure proper fit and function, accurate measurements are essential.

Time needed: 10 minutes

- Determine Aluminum Bahama Shutter Type

Hurricane shutters are constructed and rated for tropical storm defense in High-Velocity Hurricane Zones. Shutters designated for hurricane protection are made with reinforced impact-resistant louvers.

Decorative-only shutters operate exactly like hurricane-rated shutters but are built with hollow louvers that are perfect for everyday use but are less resilient to extreme force.

Both styles are manufactured with extruded aluminum alloy for impeccable strength and remarkable durability. - Measure the Width

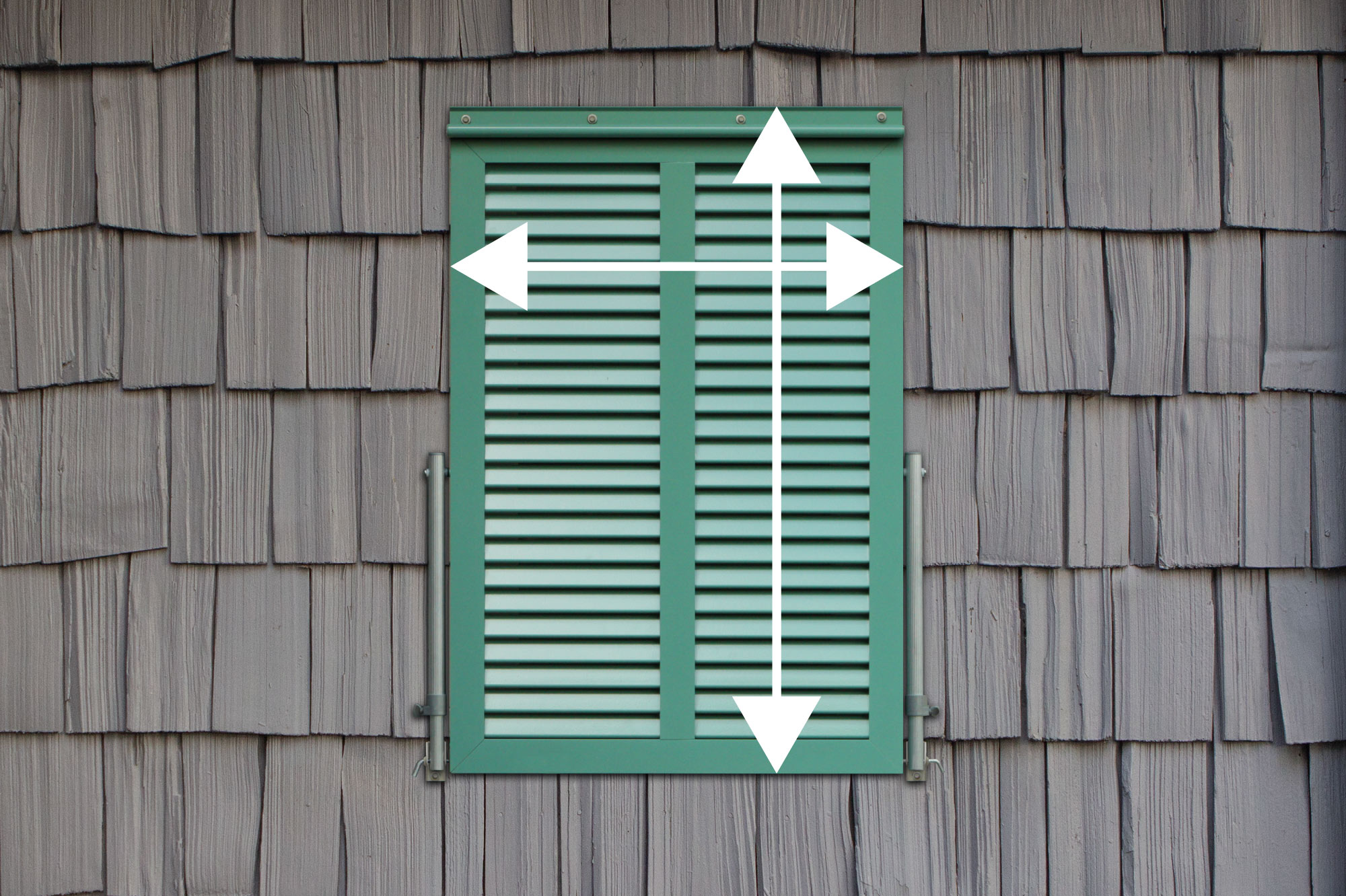

With a steel tape measure, determine the best width so the shutter overlaps the window opening by at least 1 to 2 inches on either side.

Impact-resistant hurricane shutters are offered in quarter-inch increments and decorative shutters in half-inches.

Sub-stiles are vertical members that divide the shutter into multiple horizontal louver areas. They allow the shutters to be made wider than standard panels. Narrow shutters do not require a sub-stile, while wider shutters may have one, two, or three vertical supports depending on the window width.

- Measure the Height

First, assess the future placement of the top hinge so the shutter extends beyond the top and bottom of the window opening by at least one inch. If the window has no casing or flat casing, the hinge can be mounted close to the window.

The shutter height ordered includes the shutter and the top hinge. The top hinge is permanently attached to the shutter and is 1.5″ in height.

Aluminum Bahama shutters are available in height increments that correspond with the louver spacing, about an inch and a half apart. Choose the size closest to the required dimension.

Installation screws must be properly anchored to a structurally sound foundation according to local building codes.

- Measure for an Optional Divider Rail

A divider rail is a horizontal bar that divides the shutters into top and bottom louver areas. If a divider rail is to be included, measure from the bottom of the window to the center of the division.

- Choose Shutter Lock

A secure locking mechanism is a necessary component for hurricane shutters.

Camel brackets are the building-side part of the support arms that hold Bermuda shutters in an open position. They also allow a locking-pin to pass through and into a hole in the side of the outside side stile to keep the shutter closed. Camel brackets are the most basic basic system for holding Bahama shutters closed.

Z-clamps are stored until necessary to lock a Bahama shutter closed. They are six inches wide and wrap around the shutter and screw into the building. Z-clamps are very effective in tropical storms or hurricanes.

Pin-latches are bolts embedded into the bottom rail that slide horizontally into a receiving bracket. They typically take less time to lock and can be accessed from either outside or inside the home through an open window. Inside-access pin-latches may require the shutter to be shorter to allow easy reach and operation from an open window. - Select a Color

Choose from 20 standard aluminum powder-coated finish colors, or from 174 additional RAL custom colors.

Now that you’ve taken measurements, the next step is to order custom aluminum Bahama shutters. The online system will walk you through the process of entering all the necessary details to ensure a perfect fit. Once your order is placed, expect about 8-10 weeks for manufacturing. Once they arrive, the final step is installing outdoor aluminum Bahama shutters.